Are You looking for Ways to Maximize Your Supply Chain Management Software Potential?

Get the benefits of a cloud ERP without the hassle

If you’re a supply chain leader that depends on ERP every day, you’re definitely familiar with ERP’s shortcomings. When it comes to managing all your supply chain data, providing alerts for inventory and shortage issues, driving standard work, and creating reports, ERP’s “features” are definitely limited. ERP systems are a critical part of your business, but they lack the tactical execution tools that are needed for today’s complex supply chain.

Occasionally, we hear companies ask “How is LeanDNA different than ERP?” Or, “Doesn’t my ERP already perform all the analytics my supply chain needs?” At first glance, they can seem similar. Here are the areas where ERPs need a little help - and how leveraging LeanDNA to fill the gaps results in substantial savings:

- Provides prioritized recommendations for the highest-value tasks, rather than thousands of unsorted alerts, and automatically assigns them to the right team member

- Standardizes data from multiple ERPs or data sources into one platform to promote cross-site analytics and collaboration

- Purpose-built for lean manufacturing so you can tackle inventory reduction and shortage management immediately

- Excels at project management for lean manufacturers

- Easy-to-use, online, collaborative platform houses all your communications across sites and with suppliers

LeanDNA Unlocks Cloud ERP Capabilities

To start, LeanDNA is not meant to replace your ERP. LeanDNA is a pre-built tool that quickly bolts onto your ERP’s data using one-way communication. This means:

- LeanDNA can access specific data points relevant to supply chain

- Multiple ERPs can be pulled into the same instance of LeanDNA, which brings all your data together into one common view

- LeanDNA will never write data back to your system, so the data in your ERP system will not be compromised

Prioritized Recommendations

Buyers, supply chain managers, and planners are inundated with thousands of alerts from your ERP system to modify purchase orders, change order policies, and respond to material shortages. And we do mean thousands. The alerts arrive at any time, with no indication of priority. No individual or team could effectively manage that volume of alerts!

Buyers, supply chain managers, and planners are inundated with thousands of alerts from your ERP system to modify purchase orders, change order policies, and respond to material shortages. And we do mean thousands. The alerts arrive at any time, with no indication of priority. No individual or team could effectively manage that volume of alerts!

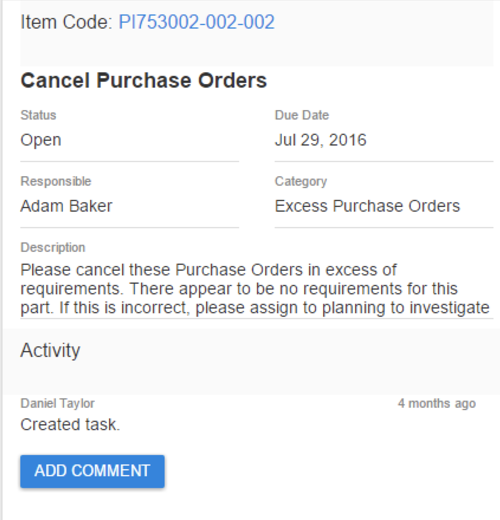

Here’s where LeanDNA comes to the rescue with Prioritized Recommendations. Instead of dumping every potential alert onto your team all at once, LeanDNA chooses the 5-10 most valuable actions each day to recommend to your team. Each task is automatically delegated to the right person, with the action, recommendation, data, and potential savings ready to go.

LeanDNA’s proprietary algorithms, artificial intelligence, and analytics run daily to create and assign recommendations. The tool considers important data points in deciding prioritization:

- average monthly usage

- MOQ

- purchase requisitions

- firmed POs

- statistical analysis of demand variability

- and other relevant factors

Anything that could influence the value of the specific task for the business.

Your team can take immediate action to save millions in inventory with reduced effort and time. Instead of digging through the masses provided by the ERP, LeanDNA has already discovered the biggest inventory opportunities. LeanDNA drives tactical savings directly from the source.

Your team can take immediate action to save millions in inventory with reduced effort and time. Instead of digging through the masses provided by the ERP, LeanDNA has already discovered the biggest inventory opportunities. LeanDNA drives tactical savings directly from the source.

Cross-site Analytics

Manufacturers today are spread out. Thanks to globalization and mergers & acquisitions, a single company might run several different ERP systems, or multiple instances of the same ERP. SAP, Oracle, Infor, Baan, even multiple homegrown systems - we’ve seen every combination. At the end of the day, you’re left with siloed data and limited internal communication.

LeanDNA standardizes your data so it can be viewed and analyzed across your network of facilities, regardless of its source. If you have shortages at one site and excess inventory at another, LeanDNA alerts your buyers and planners to transfer items, rather than putting in a whole new purchase order. That saves you money!

Not only are you avoiding expediting parts at a premium price, but you’re reducing excess inventory that will eventually be written off as obsolete.

Supply Chain Management Software Built for Lean Manufacturing

LeanDNA delivers data in an intuitive, clean, and efficient way. Creating out-of-the-box visualizations of manufacturing data makes sense. It’s hard to find trends, projections, patterns, and critical changes when your data lies solely in ERP’s exported tables. When you want supply chain data fast, a platform purpose-built for lean manufacturing gives you the right data as quickly as possible.

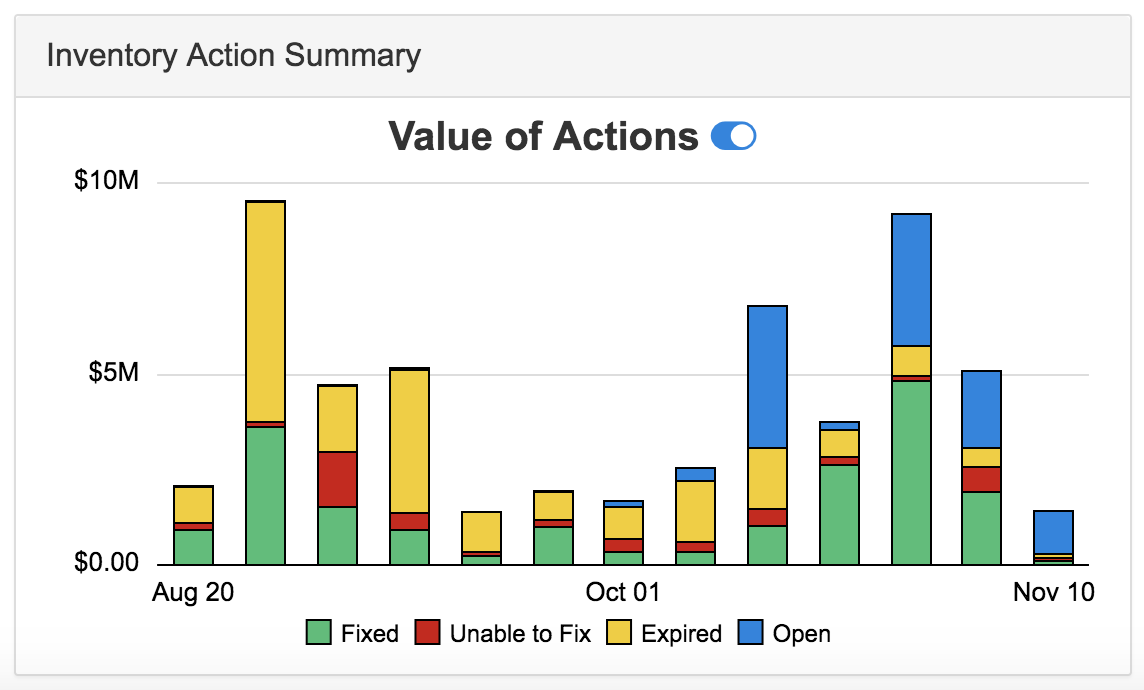

From ballooning inventory to sudden increases in shortages, charts are generated automatically and always feature the most up-to-date data. And because the platform is designed for lean and six sigma manufacturers, no initial setup is required. All the data you need to see is ready to go. Not only can you assess your current business quickly, but you can project your trendlines into the future and take preemptive action to avoid volatility.

Included Lean Project Execution

Lean manufacturing functions best when accompanied by a culture of accountability, transparency, and ownership. LeanDNA’s built-in lean project execution features promote effective, organized communication, in a way that ERP cannot.

Lean manufacturing functions best when accompanied by a culture of accountability, transparency, and ownership. LeanDNA’s built-in lean project execution features promote effective, organized communication, in a way that ERP cannot.

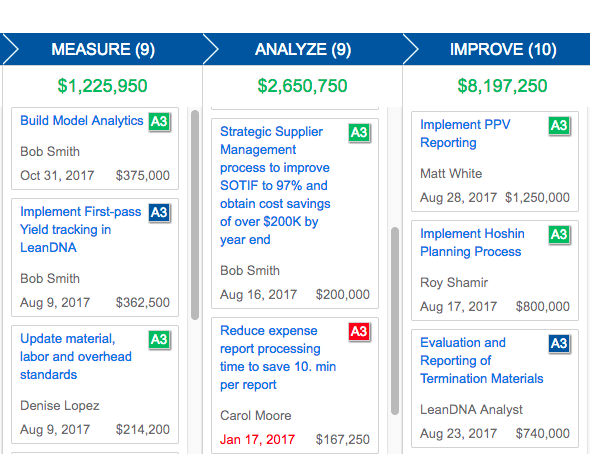

LeanDNA drives continuous improvement by managing lean initiatives tied directly to your supply chain metrics. Tasks and issues can be assigned and raised to any member of your organization so they’re alerted when action needs to be taken. LeanDNA lets you manage your supply chain and improve it at the same time. How’s that for lean?

Supplier Communication

Manufacturers don’t work in a vacuum! Each day, it’s critical that we communicate with our suppliers. Normally, this happens via disjointed emails or phone calls. You can’t let a supplier into your internal systems, of course!

But suppliers have direct access to a limited view of LeanDNA. And again, because the tool bolts onto your ERP, the security of your data is not an issue. By granting your suppliers access, they can view their current shortages and supplier scorecard to check their performance. They can also provide updates on shortages and commit dates. When areas for improvement are identified, launch a lean initiative to improve their delivery, cost, and quality scores and track progress over time. That’s right - all this can happen in one tool!

Supply Chain Management Software for the Future of Supply Chain

LeanDNA was created to eliminate shortages, and improve collaboration without burden on your teams or systems. Use LeanDNA to unlock your supply chain data and see how much your working capital can improve.

ERP on it’s own is not enough… now what?

While ERP systems are critical, it has become evident that on their own they are not achieving their full potential. It’s time to turn your ERP noise into an advantage.

Learn more about potential ERP solutions.

This medical devices manufacturer was able to save $700K in the first month with LeanDNA’s supply chain automation.

When creating Excel reports and Sharepoint documents became some team members’ full-time jobs, LeanDNA was there with a solution. By implementing their pre-built ERP connections, this medical devices manufacturer was able to assign tasks to key personnel, monitor activity around the tasks to ensure completion, and track results on subsequent reports.

Read their story.