The “unprecedented” hits to global supply chains keep coming. As demand fluctuates and shortages run rampant, the chain continues to fail at multiple vulnerable links, leaving manufacturers unable to produce, and consumers left holding an empty bag. However, like most bad situations, if you look closely enough, you can see a silver lining.

All of this was the backdrop for an April 2021 IndustryWeek webinar titled, “Going Beyond ‘Status Quo’ Supply Chains.” It featured several subject matter experts, ranging from industry analyst Bob Ferrari, Lean Manufacturing leader and CEO of LeanDNA, Richard Lebovitz, and VP of Global Operations at lngersoll Rand, Paul Aram. These practitioners and visionaries shared a wealth of real-world insight on the next big thing in execution-based inventory management: The emerging Lean-hybrid approach.

In this case, the glimmer of positivity comes from all of the gaping cracks exposed in supply chains. In particular, an acknowledgement that the “right way” to manage inventory—the decades old status quo that worked in simpler times before globalization, mass customization, and multi-tiered supply chains—no longer works.

Bob Ferrari set the stage by encapsulating the current environment that manufacturers find themselves in.

"Even before this storm, things were already brewing. COVID landed on top of an already budding customer-driven supply chain where outside forces like fast-paced customer demands came in and converged with manufacturing. It's shifting the way companies have to think about their approach. Instead of inside-out, where companies seek to optimize their 'four walls' manufacturing processes, we have to now think about the customer first, and their specific product and service needs."

"Layer that on top of COVID and now the Suez Canal issues, complex shortages of basic resources like steel, plastics, and now semiconductors. And it's not surprising that President Biden made his official order about finding ways to keep supply chains more resilient."

Bob Ferrari

Founder, Ferrari Consulting and Research Group

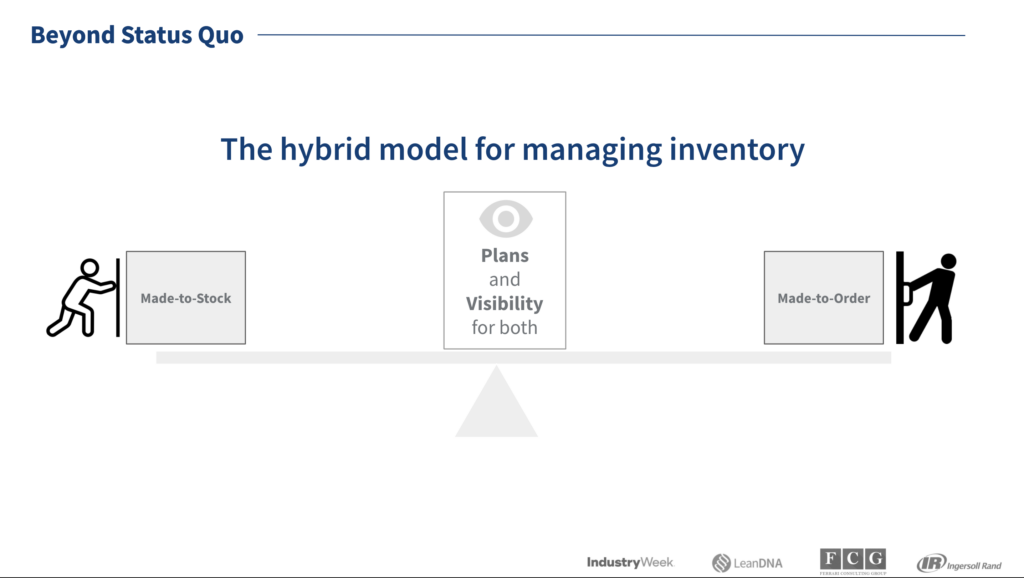

The Status Quo: Excel Runs Production

In the past, when products were often make-to-stock, supply chains were flat, suppliers were regionalized, and factories were often disconnected islands of information. Data was more sparse (often analog and visual on kanban boards), and demand was more level, making it easier to rely on forecasted demand. For the most part, shortages and excess inventory could be avoided. But those days were already over when the pandemic hit and further illuminated the need to change. As customer-centricity becomes a corporate guiding principle and products become significantly more customized, the volume of make-to-order products grows proportionally—all compounded by the exponentially more complex, globally connected supply chain and its sea of data. Manufacturers tried to juggle push and pull methods, but often ended up relying too heavily on demand planning and forecasting (Note: Forecasts tend to be wrong), and underestimated the difficulty of normalizing and prioritizing ERP/MRP data. Spreadsheets became the de facto “tool.” Now, the dirty little secret in manufacturing? ERP stands for “Excel Runs Production.”

Manufacturers tried to juggle push and pull methods, but often ended up relying too heavily on demand planning and forecasting (Note: Forecasts tend to be wrong), and underestimated the difficulty of normalizing and prioritizing ERP/MRP data. Spreadsheets became the de facto “tool.” Now, the dirty little secret in manufacturing? ERP stands for “Excel Runs Production.”

Richard Lebovitz then summed up the challenges with this status quo.

“The Status Quo... We're talking about the manual processes, the slow reaction times because of inaccurate data, the spreadsheets. That all impacts the back office of manufacturing, the people who are really struggling to make sure the factory has everything needed to deliver the products on time.

With the customer-driven outside-in supply chain model, we need to actually start at the factory, but the factory, unfortunately, has been left behind in past enterprise system transformations. And we're not talking about the factory floor, where there's a lot of automation robotics. What we're talking about is what we call the Factory Operations Management, where inventory decisions are made to ensure you have the right parts at the right time with optimized inventory. That's the challenging part, I would say, for today's enterprise.”

The critical role of the factory, Lebovitz described, is heightened when the unpredicted events happen.

“The factory is where execution happens, and this decides how well you can react to some of the challenges like COVID, or the Suez Canal, or the semiconductor shortage, or the Texas Freeze. The factory has become a key piece of manufacturing for resiliency—the ability to reroute parts, find alternative suppliers, optimize capacity, and best fill orders coming in."

Richard Lebovitz

Founder and CEO, LeanDNA

Paul Aram wrapped up the webinar by explaining exactly how he built a Lean-hybrid approach in his factories at Ingersoll Rand to stay agile and keep customers happy.

“We’re trying to develop a strategy and operation to improve our customer service levels and use that as a differentiator. So we're trying to get to a specified on-time delivery percentage and lean time mix, which we identified by product group and by Standard to Order (STO), Configure to Order (CTO) and Engineer to Order (ETO)."

"The ETO products, by definition, are products that have to go through some sort of engineering function before they can actually be launched into the factory. There's some sort of part or color or something that's different. With those types of products, using Kanban and those sorts of pull systems isn’t really appropriate. We want to be using MRP, and therefore, we want to be using some sort of good method like LeanDNA to help us to optimize the way that we use the MRP process."

"In a way, all of what we do in terms of our inventory planning is related to the service vision definition that we've started with. That allows us to identify which parts go on each replenishment method, whether we're going to use Kanban, whether we're going to use VMI, and which parts we're going to continue to run on MRP.”

Paul Aram

Vice President of Global Operations, Ingersoll Rand

Paul, Bob, and Richard covered much more in the session, which is available in its entirety here. But the big takeaway (no surprise) is “what got us here in manufacturing won’t get us there.” The factory can be the strongest link in the supply chain, but the status quo of juggling push and pull with spreadsheets as exposed during our perfect supply chain storm must change; it isn’t resilient, doesn’t scale, and will always lead to excess inventory and critical shortages (aka unhappy CFOs or unhappy customers). Instead, the hybrid approach that thoughtfully and seamlessly interweaves the best of lean thinking with modern MRP management is the light at the end of a long string of dark days.

To learn more about the processes and tools used by Paul and his team at Ingersoll Rand, reach out to one of our experts to chat.