Does your factory have ERP purchase order overload warning signs? You know, those bright yellow triangles? Perhaps it has an exclamation mark for caution, or a lightning bolt to represent high voltage area. Maybe it even features a skull & crossbones to signal that dangerous chemicals (or pirates) are present. No matter the sign, they clearly mean one thing: WARNING.

As a supply chain manager, you probably wish you had a sign like that for your team to help them with the purchase order process. Maybe it would be a triangle with a broken-down delivery truck meant to represent an impending shortage. Whatever it would look like, it’d be amazing to give your buyers a sign of which could increase your ERP purchase order risk.

Well, there may not be a physical symbol you can place in your office, but there are plenty of warning signs to look out for. Here are four warning signs your POs could cause trouble.

1) You Are Ignoring Exception Messages

1) You Are Ignoring Exception Messages

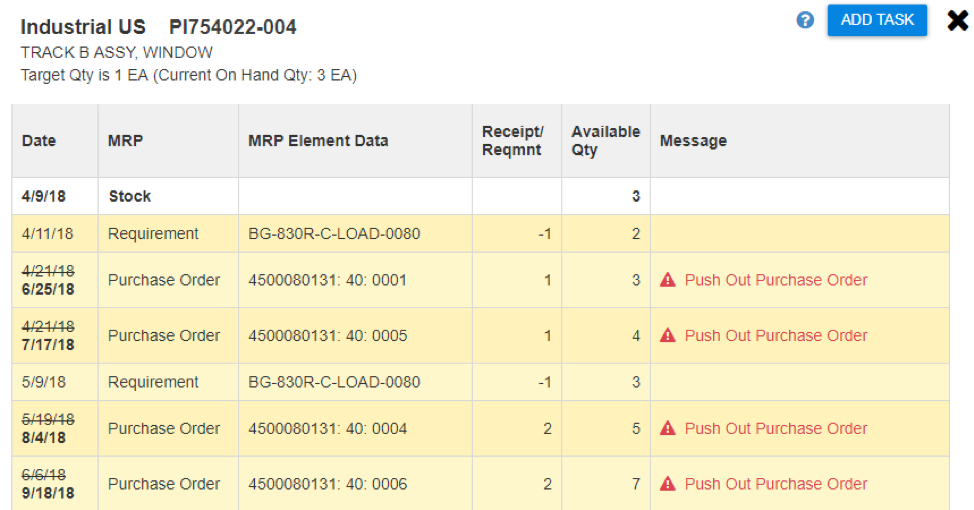

If you think of yourself as a detective investigating POs, exception messages would be your clues. These messages provide insight into which POs need to pushed out and which ones need to be expedited. But ERPs produce so many exception messages – sometimes even thousands each day – that even the most efficient teams could never address them all.

Here’s what to look out for as you hunt for the high-value clues. Are there certain POs that are regularly ignored? Specific parts or categories that too often get pushed to the back burner? Those might be warning signs to watch.

But how do you sift through all that volume to find the most important exception messages? That’s the tricky part. At LeanDNA, we connect with ERPs to create a high-powered clue-finding machine. That leaves it up to you to follow the right clues to success.

You may not be able to take every action recommended, but it is important to at least do some digging on each high-value task. If you are told to bring in a PO, there is probably a good reason, like preventing a material shortage or making up for a scrapped item. Ignoring that message without at least investigating it can cause all sorts of trouble.

Make sure your important POs are easy to identify and act upon. We recommend capturing those messages in a Stock/Requirement list. These messages can also be included PO reports so they are able to see everything on one page. This will help turn your team into a whole group of PO super-sleuths like Sherlock Holmes!

Make sure your important POs are easy to identify and act upon. We recommend capturing those messages in a Stock/Requirement list. These messages can also be included PO reports so they are able to see everything on one page. This will help turn your team into a whole group of PO super-sleuths like Sherlock Holmes!

2) PO Dates Do Not Match Delivery Expectations

One reason that an exception message may be ignored is because the PO date in your system doesn't match your true delivery expectations. Your system says Friday, but you need it to arrive on Tuesday. Even if you communicate your true expectations with the supplier, you are at risk until the dates are updated in the system.

You must make sure your team takes proper steps to ensure that the date on the PO reflects when you expect the part to be received. For example, your buyer may tell the supplier a delivery needs to be moved in, but the PO was never updated. If the supplier forgets, as is often the case since we are all busy, they will just ship to what is on the PO. That PO was at risk the entire time, simply because it did not accurately reflect when you needed the delivery.

Establish a standard work for keeping your POs updated and accurate. That way, your system and your people will be completely in sync, reducing your potential for error.

3) The Real Data Can Only Be Found Inside Someone's Head

Does this sound familiar to you? Bob has worked in your office for 30 years. He knows every nook and cranny of the place better than the janitor. He is aware of when a program build is coming and which changes are seasonal. Because of this, your ERP really should be Bob's brain. But unfortunately, it is not.

Bob’s thoughts may be updated automatically, but your ERP is not. Much like #2 above, this leaves POs at risk. Bob won't be around forever. And the guy deserves a vacation every once in a while, don’t you agree? Your data needs to be accessible to every member of your team and tracked in a system.

To do this, a lot of companies need to start by cleansing data in their ERP. That can be scary, but it has a lot of benefit! Need help? Here’s what you need to know.

4) How to Improve On-Time Delivery to Customers through Supplier Collaboation

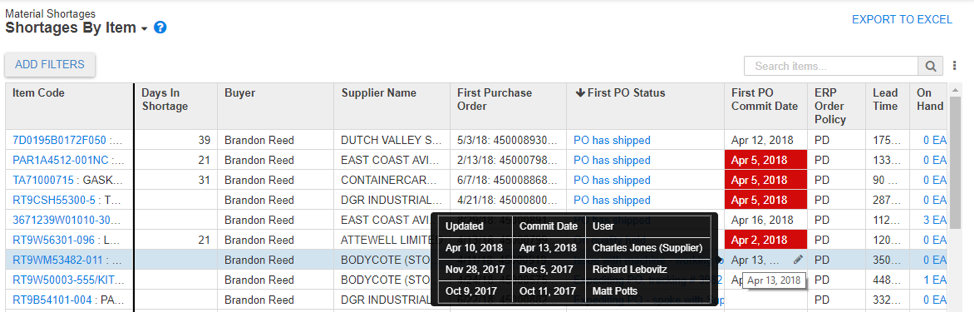

We know that working with suppliers can be tough. When suppliers provide status updates on your POs without being asked, that’s a major win. The next level is to make sure they are held to those updates. Ever had a supplier provide a commit date in your system only to change it a week later without telling anyone?

Without a watchful eye, this would easily go unnoticed. Make sure you have a system or process in place that helps you see those changes, even if your supplier is trying to be sneaky. We recommend capturing timestamps for entry of statuses or commit dates so you do not lose track of the history of entries. This helps you see when dates have been changed and a PO may be at risk. Talk about a warning sign!

Without a watchful eye, this would easily go unnoticed. Make sure you have a system or process in place that helps you see those changes, even if your supplier is trying to be sneaky. We recommend capturing timestamps for entry of statuses or commit dates so you do not lose track of the history of entries. This helps you see when dates have been changed and a PO may be at risk. Talk about a warning sign!

What are your ERP Purchase Order Warning Signs?

Not all warning signs are neon yellow or fiery red. But even so, some of the most important warnings are right in front of your eyes. Are you and your team equipped with the right data at your fingertips and aware of what to look out for? How many POs are exhibiting warning signs right now, and how are you getting in front of the issues?

Advanced technology can help reduce the overload of noise from ERP purchase orders.

By providing actionable insights into your ERP system, new advancing technology solutions can improve supply chain performance in more ways than one. Improving supplier collaboration is the best way to make sure that you are getting the right information at the right time.

Check out these 5 ways you can strengthen your supplier communication.

The landscape of the global supply chain is constantly changing.

In today’s new shortage economy there is not only shortages of materials, but a skilled labor shortage in manufacturing. When developing a continuous improvement process, it is important to not only consider the current state of the supply chain, but how manufacturers can be resilient and responsive to changes, no matter the state of the economy.

Become resilient.