Inventory ties up a massive amount of working capital – to the tune of $459 billion dollars. That makes up nearly 3% of the entire United States GDP! Successful inventory management is critical to becoming a leader in supply chain in every industry vertical. And manufacturers are looking for solutions to drive inventory management improvement.

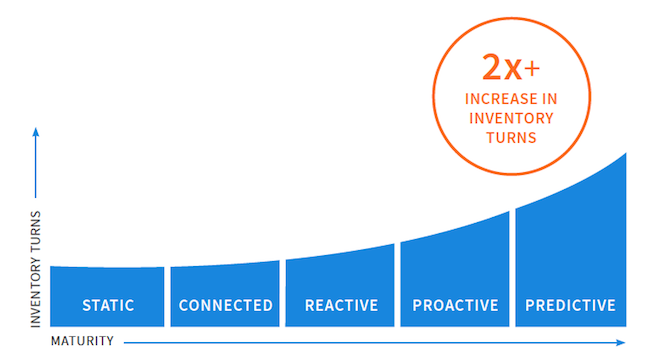

What does it take to improve inventory turns by 200% or more?

The first step is to understand your organization’s inventory management maturity. Then, make room for supply chain improvement!

Maturity in inventory management ranges from heavily manual processes to advanced, predictive management. Based on our experience working with global manufacturers and industry best practices, we’ve assembled the Inventory Management Maturity Curve in our latest whitepaper to help you understand your organization’s potential for inventory management improvement.

Understanding The Inventory Management Maturity Curve

The Inventory Management Maturity Curve has 5 stages, ranging from lowest to highest impact on improving inventory turns:

- Static

- Connected

- Reactive

- Proactive

- Predictive

Supply chain professionals should aim for the Proactive or Predictive stages of inventory management. These manufacturers can see 200% or greater improvements in inventory turns. The Proactive and Predictive stages represent the best of both the present and future of supply chain, incorporating Industry 4.0 technologies such as Artificial Intelligence (AI), machine learning, and more.

But today, many supply chains exist within the first two maturity stages: Static or Connected. These organizations do not fully optimize inventory, leaving money on the table.

Static or Connected supply chains may have set inventory management policies and procedures in place, but continuous improvement is limited. Data can become outdated quickly, collaboration is difficult, and too much time is spent “firefighting” - solving problems only when they get too big to ignore. We also find a lot of internal subject-matter experts who keep the inventory management machine running, often with outputs like the “Bob report” or the “Guillermo report” being a critical source for information.

Sound familiar? That’s okay! Significant improvement is absolutely achievable. And it might not take as long as you think.

One interesting thing about this maturity curve is that progression does not have to be linear. If your organization is currently in stage 1, you can take immediate steps to get to stage 4 or 5. You don’t have to slowly traverse through each stage individually, but can quickly reap the returns with an improvement-oriented culture.

Benefits of Inventory Management Maturity

What’s the benefit of moving further along the maturity curve? Mature manufacturers have:

- More robust inventory management practices

- Better supply visibility

- Fewer shortages and better on-time delivery performance

- Improved working capital

- More efficient teams

- And of course, higher inventory turns!

Manufacturers that take the time to focus on their inventory management maturity see great benefits across their supply chains. Where do you fall in the Inventory Management Maturity Curve? How can your organization grow within inventory management and deliver more business value? What will it take for you to advance to the Proactive or Predictive stage?

Find out in the free Inventory Management Maturity Curve whitepaper! In it, you will find:

Find out in the free Inventory Management Maturity Curve whitepaper! In it, you will find:

- In-depth analysis on the key characteristics, advantages, and challenges of each maturity stage

- Common tools used at each stage

- How to evaluate your company’s current inventory maturity stage

- Strategies to advance your supply chain’s maturity

- The measurable impact advancing to a new stage can have on your business

- ...and more!

Are your methods to improve inventory turns missing something?

When developing inventory management tools, it is a vital first step to create or evolve your Plan For Every Part (PFEP). As the global supply chain grows increasingly complex, the need for the PFEP only grows, and it is essential to optimize the policies that define your Plan For Every Part to reach your inventory optimization goals.

Check out some PFEP best practices.

Are you looking to see the benefits of inventory optimization?

Tony Gonzalez, the global lean supply chain manager at Electrical Components International (ECI), accelerated critical inventory practices by developing two key initiatives—an inventory attack team and a shortage attack team. His strategy, in alignment with advanced inventory management tools, led to reduced critical shortages an average of 30 percent across their sites in the first six months.