Let LeanDNA work overnight so you don’t have to

The key to a successful supply chain digitization

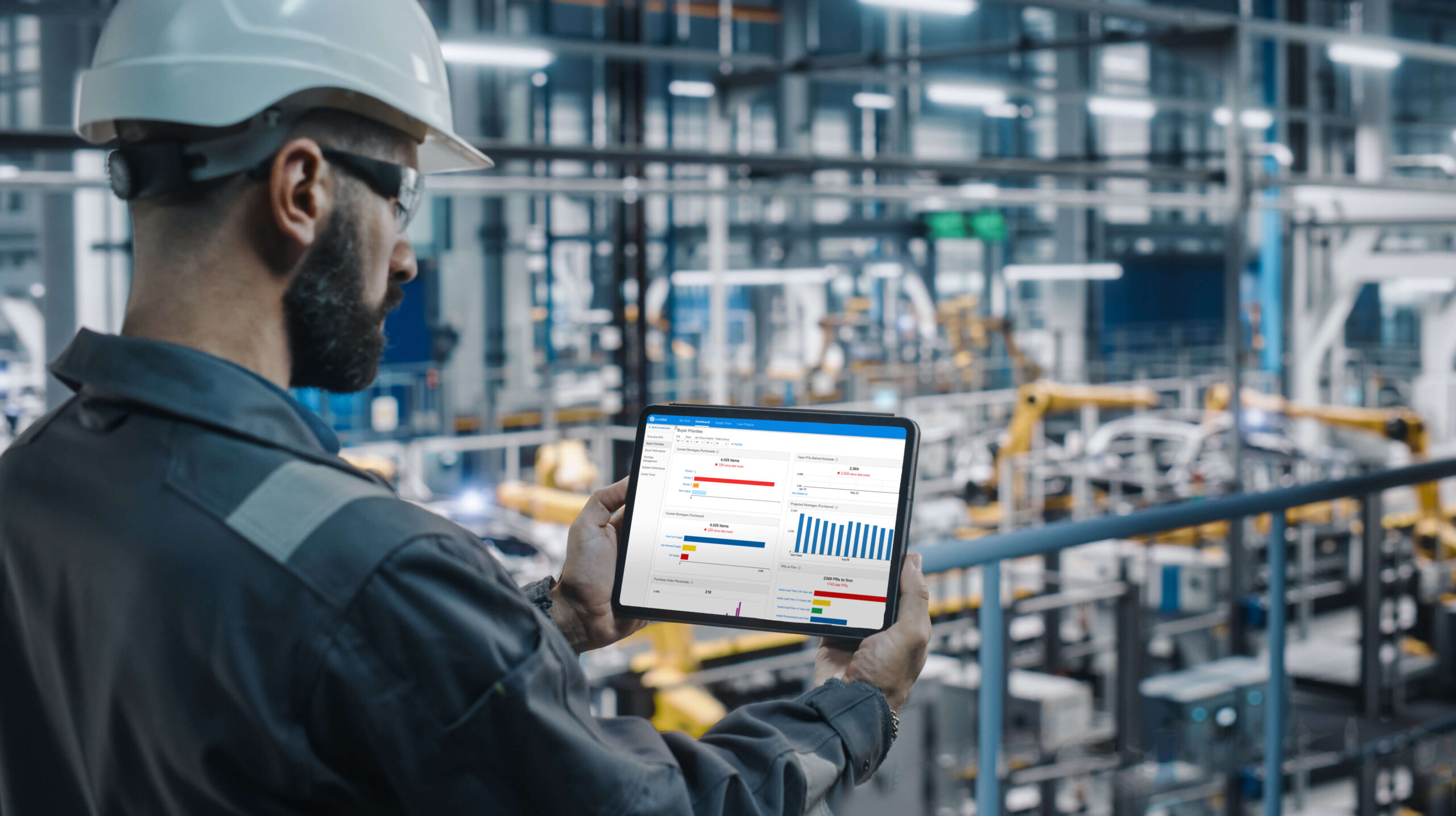

LeanDNA bridges this gap by connecting sites, systems, and suppliers to improve visibility and efficiency. Unlock full situational awareness around critical shortages, cost savings opportunities, and supply chain performance to continuously improve and maximize the value across your teams and technology.

Digitally thread your supply chain to create a collaborative ecosystem

Unlike common supply chain management software, LeanDNA is the only available platform that connects your teams by providing readily available prescriptive analytics and streamlined communication to mitigate current and future shortages, reduce excess inventory, and improve your team’s efficiency.

Demand to delivery visibility

Inventory & workflow optimization

Prioritized actions for execution

Truly integrated supply chain management through synchronization

With LeanDNA, industry leaders can reach new milestones with unmatched automatic daily insights that make collaboration, change management, performance tracking, and right-sizing inventory faster and easier than ever before.

Supply chain resilience strategies implemented without the heavy lifting

LeanDNA’s team of supply chain experts can operationalize even the messiest sets of data from any ERP system to standardize reporting, and improve data health, and reliability.

- Fast user adoption and simple change management

- Synchronizing processes, reporting, knowledge sharing, and performance tracking

- Unified view of information across systems, suppliers, and sites

Why LeanDNA is one of the best supply chain saas companies

Aerospace & defense

Spirit AeroSystems is one of the world’s largest manufacturers of aerostructures for commercial airplanes, defense platforms, and business/regional jets. In 2020, the Coronavirus crisis shut down world travel and global demand for commercial aircrafts plummeted. This led to canceled, deferred or changed orders. Spirit responded by shuffling the master schedule and configuring the airplanes differently. However, the company needed help solving timely delivery of highly customized products, increased reliability on globalized supply, and dramatic rate changes. Learn how Spirit AeroSystems Reduced Inventory by 16% with LeanDNA.

Automotive

E-ONE is the global full-spectrum manufacturer of pumpers, tankers, aerial ladders and platforms, rescues, industrials, and aircraft rescue and firefighting vehicles (ARFFs). The pioneering manufacturer uses advanced engineering, fully integrated manufacturing and a highly engaged dealer network to continually deliver strength through excellence. When the semiconductor shortages began impacting companies around the world, halts and delays could have impacted E-ONE’s inventory and production, had the company not implemented LeanDNA in 2019. Learn how E-ONE reduced inventory shortages by 39% within 7 Months.

Industrial

As a leading manufacturer of business and residential building products, HNI’s highly complex manufacturing process is about 95% build-to-order which includes 400 suppliers, a high number of SKUs, and customizable options. HNI began exploring LeanDNA’s analytics platform with the goal of finding a solution to easily identify issues to proactively plan and respond faster when they arise. The company looked to improve on-time delivery, optimize inventory and reduce operational costs by aggregating, sorting, and organizing complex data sets. Learn how HNI improved on-time and completed shipment rates by 20% with LeanDNA.

LeanDNA Named Industrial Data Solution of the Year in the 2023 Data Breakthrough Awards >>

Medical devices

An innovative world leader in medical device manufacturing with over a billion dollars in annual revenue was struggling to optimize manufacturing operations. Though Oracle ERPs were implemented across the company’s 20 sites located all around the world, results were tracked at each site and bringing data together for a holistic view of the supply chain was a major challenge. Standardizing work to meet company expectations was difficult and improvements made were difficult to tie to KPIs or actual dollars saved. Learn how the company saved $700K in the first month.

Explore the only inventory optimization and execution platform for global manufacturing.